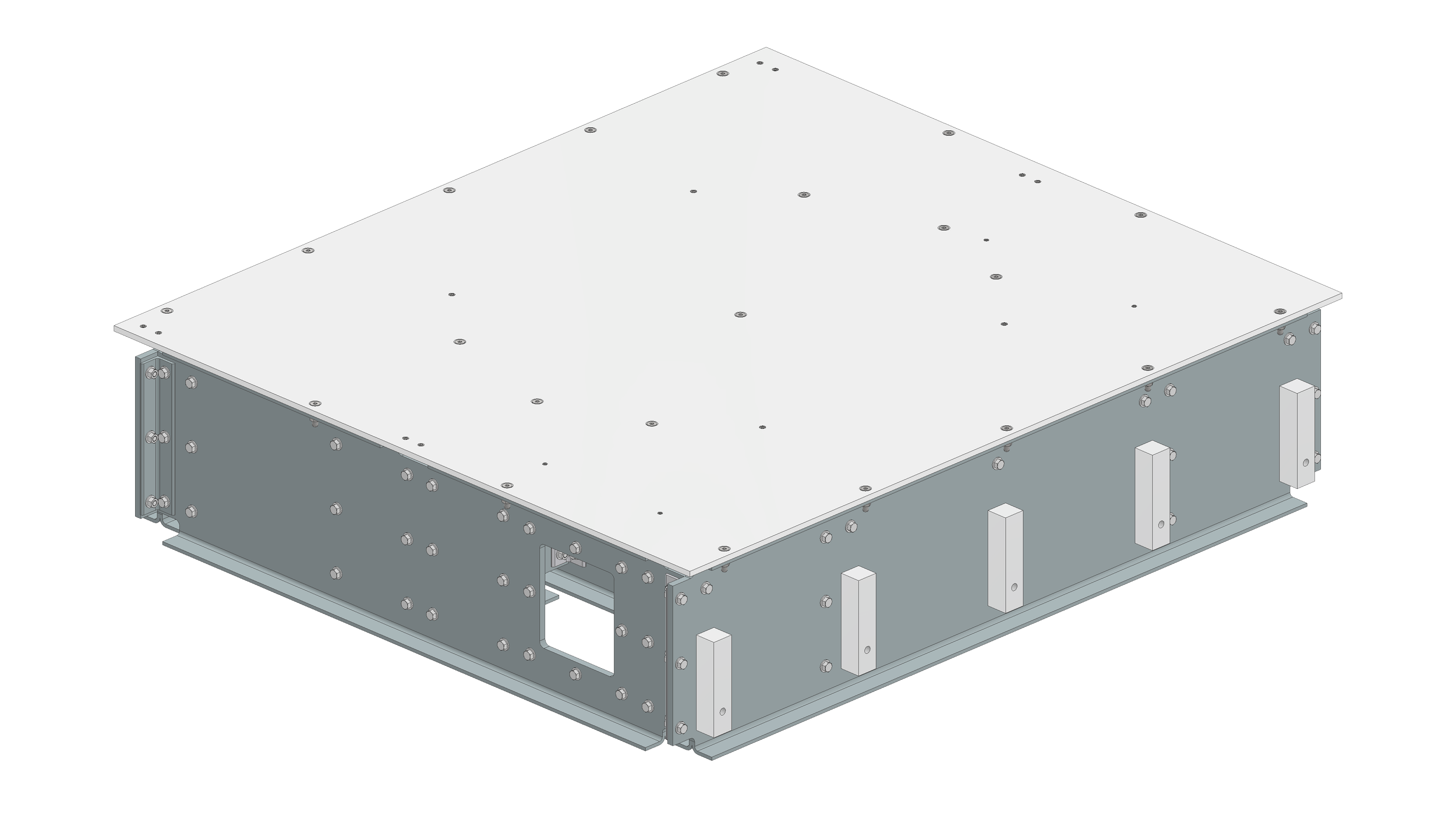

Shielded Pedestal for Wafer Inspection Systems

KLA Surfscan SP5

Overview

Tool Platform: Surfscan SP5

Solution: Compact, fully enclosed precision pedestal

Primary Benefit: Ultra-stable, vibration-isolated inspection environment

Application: Unpatterned wafer inspection and metrology

Customer & Application

Fulcrum engineered a custom machine base pedestal for a leading semiconductor equipment manufacturer supporting advanced wafer inspection platforms developed by KLA. The pedestal was designed to provide a stable, interference-resistant foundation for sensitive optical inspection systems where vibration control, environmental shielding, and precise integration are critical to measurement accuracy.

Challenge: Protecting Optical Sensitivity in Inspection Environments

The Surfscan SP5 system requires an exceptionally stable and vibration-isolated environment to perform accurate unpatterned wafer inspection. External vibration, ambient interference, or structural instability could negatively impact optical measurements. The machine base also needed to support seamless tool integration, including precise access and mounting locations, while maintaining a compact footprint suitable for fab environments.

Fulcrum’s Engineered Solution

Fulcrum developed a compact, heavily shielded pedestal engineered to create an ultra-stable inspection environment. The fully enclosed, reinforced structure minimizes external interference and enhances vibration isolation, protecting the tool’s sensitive optical components. Precisely located access ports and mounting points ensure accurate alignment and seamless system integration, delivering a robust foundation optimized for high-precision wafer inspection.

Results

Delivered a vibration-isolated, interference-resistant foundation for optical inspection

Protected sensitive components through a fully enclosed pedestal design

Ensured precise alignment and seamless integration of inspection systems

Supported consistent, repeatable performance in fab inspection environments