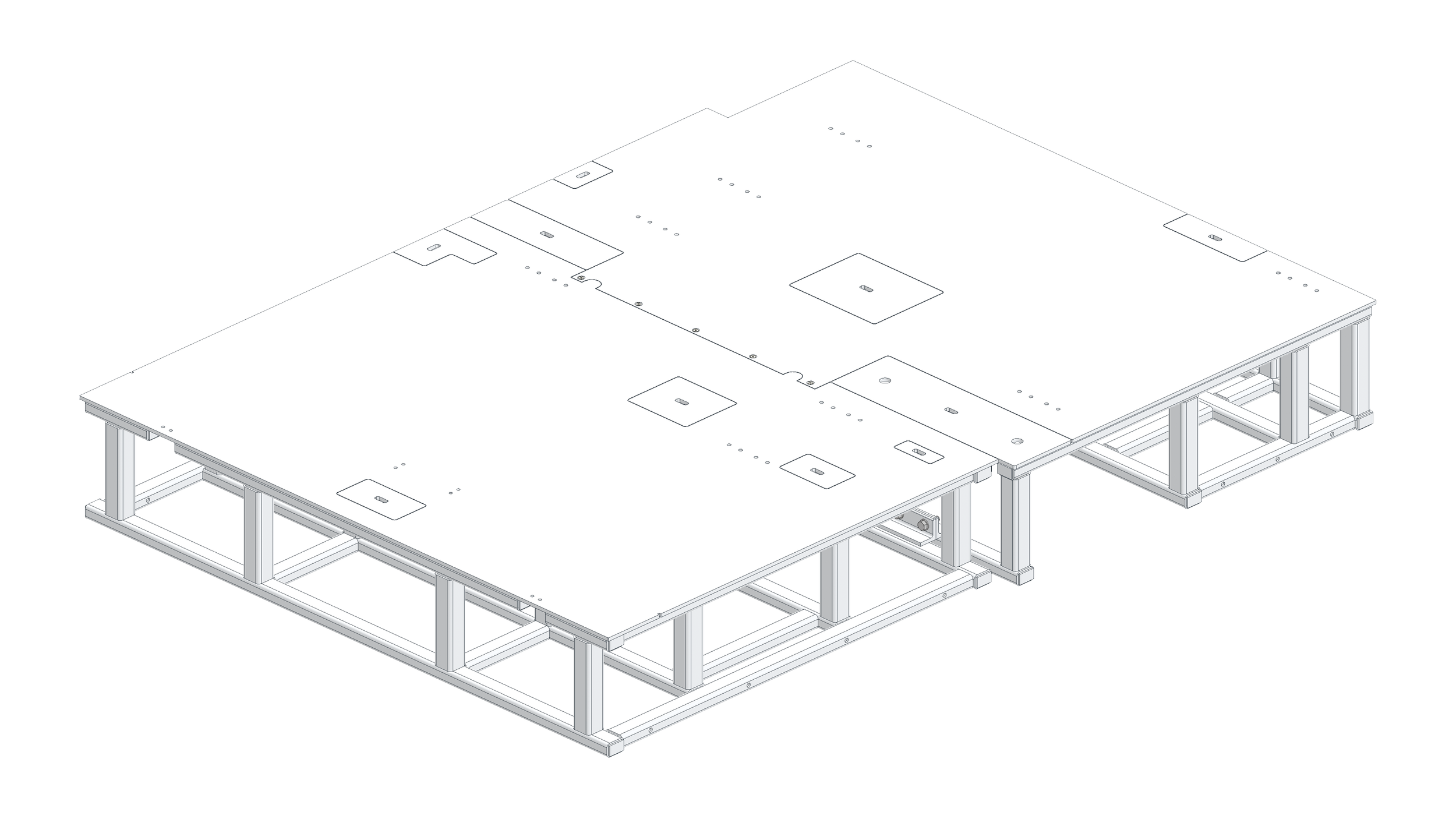

Open-Frame Pedestal for Coater/Developer Track Systems

TEL PRO AP

Overview

Tool Platform: PRO Coater/Developer track system

Solution: Open-frame, welded modular pedestal

Primary Benefit: Rigid support with full utility accessibility

Application: Photoresist coating and development processes

Customer & Application

Fulcrum engineered a custom machine base pedestal for a leading semiconductor equipment manufacturer, utilizing modular coater/developer track systems developed by Tokyo Electron. The pedestal was designed to provide a rigid, level foundation for multi-module track configurations while allowing efficient routing of plumbing, exhaust, and electrical utilities in high-throughput fab environments.

Challenge: Modularity and Access for Track-Based Tools

Coater/developer track systems require a machine base that can support multiple process modules while maintaining precise alignment across the entire tool length. At the same time, the pedestal must allow unobstructed access for routing and servicing utilities beneath the system. The challenge was to deliver structural rigidity and levelness without enclosing the base or restricting access to critical services.

Fulcrum’s Engineered Solution

Fulcrum developed an open-frame, welded machine base engineered for strength, modularity, and accessibility. The robust frame provides a rigid, level platform capable of supporting multiple PRO track modules, while the open design allows plumbing, exhaust, and electrical utilities to be routed cleanly from below. Precision-marked top plates ensure accurate placement and secure mounting of each track component, supporting consistent alignment and long-term system stability.

Overview

Delivered a rigid, level foundation for modular coater/developer track systems

Enabled efficient routing and service access for system utilities

Ensured precise placement and alignment of multiple process modules

Supported reliable, high-throughput operation in fab environments